I am 25 and a college graduate. My reason for contacting you is to seek advice from one of the premier luthiers in the industry.

I am unhappy with my current profession, and have long dreamed about being a luthier and building/repairing guitars. However, as of right now my current situation with my family does not allow me to attend a school for lutherie, and there are no luthiers where I live.

My question is regarding learning the craft. I am more than willing to take my bumps and bruises in learning. I have purchased your book on guitarmaking as well as two others, and will be building my first guitar with my father-in-law soon. While he is a retired carpenter, I have no experience with woodworking.

Can you provide any advice as to how I could begin and progress competently as a luthier even though I will essentially be self-taught? What are the best ways to be able to apprentice under an established luthier? I am willing to do whatever is necessary to enter the field,

===========================================

I'll start with the second question, "what are the best ways to be able to apprentice under an established luthier?" You would have to start by finding one that needs an apprentice to help him in his shop. That would be extremely rare and fortunate, like hitting the lottery. But take a step back first: assuming you could find a working luthier willing to take you on as an apprentice, you need to thoroughly think through the kind of investment of time and money that you would be undertaking. I imagine this would be a daunting prospect, since you have only recently invested a great amount of time and money in the pursuit of your college degree. Are you prepared to make another such large investment? That would be tough, I imagine, putting myself in your shoes. Are you being realistic?

If the number of working luthiers willing to take you on is limited, the number of working luthiers willing to take on, teach a neophyte AND pay any kind of wage is probably infinitesimally small. You would have to defray all your moving, lodging and living expenses for the year or two, or three, that it would take to a) prove to the luthier that you're manually and emotionally competent to complete the required tasks and not become an annoyance or distraction in his studio and b) become productive enough to be able to equitably repay the luthier's time and attention to your education. I do not presume to know what your financial situation is, but I would guess that most recent college grads nowadays would have a hard time making that kind of commitment.

Then, of course there are the luthier schools. That's one way to begin an entry into the field, although learning in a classroom situation is learning in an environment which is quite alien to the reality of the actual trade. The building method you learn in a school is a method which has been adapted to the necessity of teaching many students in a room sharing the attention of usually, an instructor who is only a little more experienced than the students. That is what has come to my attention as the way things are in many of these schools. It is a distant reality from making a living in a custom guitar-making studio. But you do get to complete a guitar or two, and get to be walked through the maze of steps and techniques that are required to complete the task--so it can be a reasonable first step towards your goal.

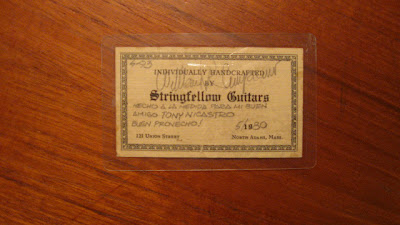

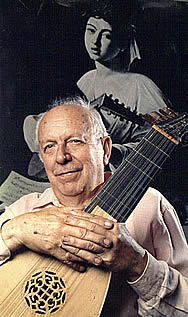

As far as teaching yourself the craft, assuming you have the not only the resources but the right amount of persistence and commitment hard-wired into your personality, you can assume it's going to take you twice, maybe three times longer to achieve the same level of technical proficiency as someone leaving a professional luthiers' studio as a journeyman. Then you have to build your own market. But I know a dozen people who have done exactly that. You only need to start with a space, a basic complement of tools and start with Chapter One of my book--or somebody else's book. It's one step in a journey of a thousand steps: becoming a successful luthier is akin in time and effort to becoming a successful artist of any other kind.